Zvigadzirwa

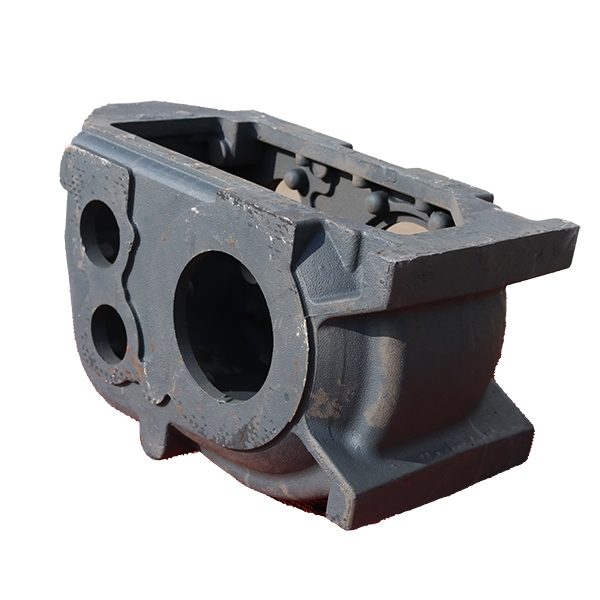

Y2-2401101 Gearbox Hood

Chigadzirwa chimiro

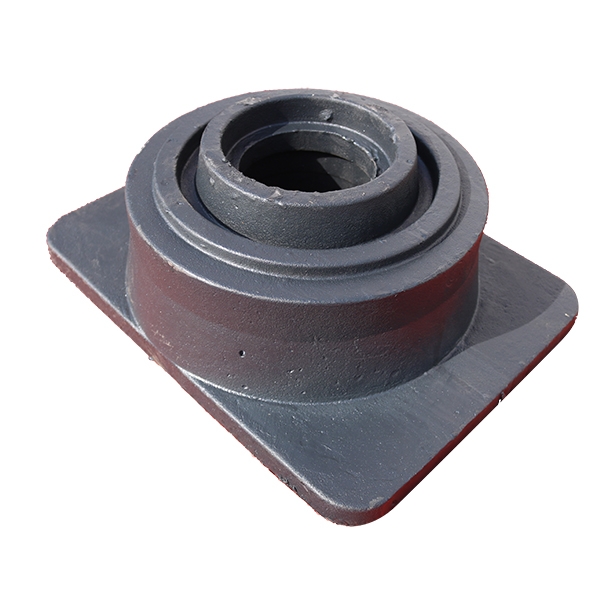

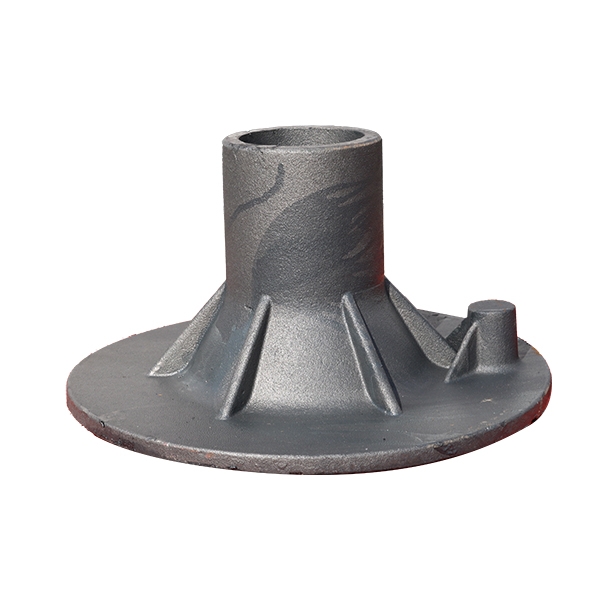

Yakarasika foam kukanda (zvakare inozivikanwa seyakajairika casting) yakagadzirwa neFoam Plastiki (EPS, stmma kana Saizi) Zvakagadzirwa zvikamu zvikaita Nekurongedza kuunganidza (kusimbiswa), kutsvedza uye kufema) uye kwakaomeswa, kunovigwa mune yakaoma Quartz jecha uye yakaiswa kune matatu-matatu-dimusi vibration modhi. Simbi yakanyungudutswa yakadururwa mubhokisi rejecha rakaumbwa pasi pekumanikidzwa kwakaipa, zvekuti polymer yekunyora kwemhando inotsveneswa uye apurasitiki, uye yakabva yatorwa. Nzira nyowani yekukanda inoshandisa simbi yekutsiva iyo imwe-yenguva-nguva yekukanda casting maitiro akaumbwa mushure mekutonhora uye kusimbisa kuburitsa castings. Yakarasika foam casting ine hunhu hunotevera: 1. Kukanda ndezve kunaka kwemhando uye mutengo wakaderera; 2. Zvigadzirwa hazvisi zvishoma uye zvakakodzera kune ese saizi; 3. Yakakura chaiyo, yakatsiga, isina kuchena, uye isingasviki machina; 4. Kuremara kwemukati kwakaderedzwa zvakanyanya uye chimiro chekukanda chinovandudzwa. Dense; 5. Inogona kuziva yakakura-chiyero uye kugadzirwa kukuru; 6. Izvo zvakakodzera kugadzirwa kukuru kwekugadzirwa kwechikanda zvakafanana; 7. Izvo zvakakodzera kushanda kwebhuku uye otomatiki musangano mutsara wekugadzira uye kuvhiya kutonga; 8. Kugadzirwa kwekugadzira kwemutsara wekugadzira kunosangana nezvinodiwa zvezvakatipoteredza dziviriro technical parameter. ; 9. Zvinogona kuvandudza kwazvo nzvimbo yekushanda uye yekugadzira yekugadzira yekukanda tambo yekugadzira, kuderedza kushanduka kwebasa, uye kuderedza kushandiswa kwesimba.

Tsananguro yechigadzirwa

Yakarasika foam kukanda (zvakare inozivikanwa seyakajairika casting) yakagadzirwa neFoam Plastiki (EPS, stmma kana Saizi) Zvakagadzirwa zvikamu zvikaita Nekurongedza kuunganidza (kusimbiswa), kutsvedza uye kufema) uye kwakaomeswa, kunovigwa mune yakaoma Quartz jecha uye yakaiswa kune matatu-matatu-dimusi vibration modhi. Simbi yakanyungudutswa yakadururwa mubhokisi rejecha rakaumbwa pasi pekumanikidzwa kwakaipa, zvekuti polymer yekunyora kwemhando inotsveneswa uye apurasitiki, uye yakabva yatorwa. Nzira nyowani yekukanda inoshandisa simbi yekutsiva iyo imwe-yenguva-nguva yekukanda casting maitiro akaumbwa mushure mekutonhora uye kusimbisa kuburitsa castings.

Yakarasika foam casting ine hunhu hunotevera: 1. Kukanda ndezve kunaka kwemhando uye mutengo wakaderera; 2. Zvigadzirwa hazvisi zvishoma uye zvakakodzera kune ese saizi; 3. Yakakura chaiyo, yakatsiga, isina kuchena, uye isingasviki machina; 4. Kuremara kwemukati kwakaderedzwa zvakanyanya uye chimiro chekukanda chinovandudzwa. Dense; 5. Inogona kuziva yakakura-chiyero uye kugadzirwa kukuru; 6. Izvo zvakakodzera kugadzirwa kukuru kwekugadzirwa kwechikanda zvakafanana; 7. Izvo zvakakodzera kushanda kwebhuku uye otomatiki musangano mutsara wekugadzira uye kuvhiya kutonga; 8. Kugadzirwa kwekugadzira kwemutsara wekugadzira kunosangana nezvinodiwa zvezvakatipoteredza dziviriro technical parameter. ; 9. Zvinogona kuvandudza kwazvo nzvimbo yekushanda uye yekugadzira yekugadzira yekukanda tambo yekugadzira, kuderedza kushanduka kwebasa, uye kuderedza kushandiswa kwesimba.

Unoda kukurukura zvatingakuitira?

Ongorora uko mhinduro dzedu dzinogona kukutora.